SPM Services

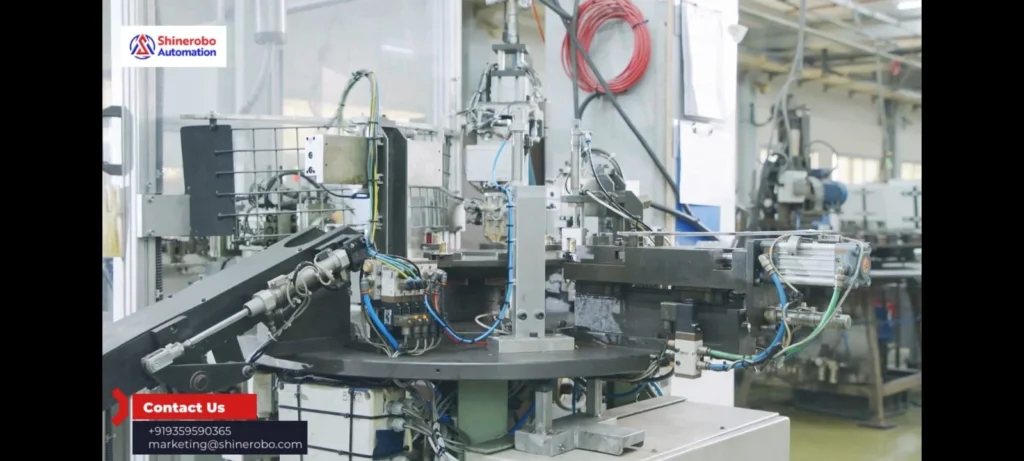

Special Purpose Machine: Shinerobo Automation Pvt. Ltd.

aShineRobo Automation is a leading Special Purpose Machine design provider. Our resident SPM specialist’s designers bring a wealth of experience and expertise to the table. With a keen eye for detail and a deep understanding of mechanical systems, they craft bespoke solutions tailored to our clients’ unique needs. From conceptualization to execution, our designers ensure that every project achieves optimal functionality and efficiency. Our team of experienced engineers and designers specializes in developing custom BiW fixtures and SPM solutions tailored to your specific needs and requirements.

The scope of designing Special Purpose Machines (SPM) and Body in White (BiW) fixtures and components involves a range of tasks and considerations tailored to the specific needs of manufacturing processes in automotive and other industries. Here’s an overview of the scope for each:

Special Purpose Machines (SPM) Design

Requirement Analysis

Understanding the specific manufacturing requirements and challenges that necessitate the development of SPMs. This involves collaborating with production engineers and stakeholders to identify the desired outcomes.

Conceptualization

Brainstorming and generating conceptual designs for SPMs that address the identified requirements. This may involve creative problem-solving to devise innovative solutions that optimize productivity, efficiency, and quality.

Mechanical Design

Creating detailed mechanical designs for SPMs using Computer-Aided Design (CAD)/ Catia/ Solid Work/ Solid Edge software. This includes specifying the structural framework, mechanisms, actuators, and other mechanical components required for the machine's operation.

Documentation

Creating comprehensive documentation including assembly drawings, part lists, operating manuals, and maintenance procedures to facilitate the manufacturing, installation, and maintenance of the SPMs.

Manufacturing Support

Providing support during the fabrication, assembly, and commissioning of the SPMs to ensure they meet the specified requirements and performance criteria. This may involve collaborating with vendors, suppliers, and technicians.

Electrical and Controls Design

Designing the electrical and control systems of SPMs, including sensors, actuators, PLC (Programmable Logic Controller) programming, HMI (Human-Machine Interface), and safety features. Integration with automation and Industry 4.0 technologies may also be considered.

Prototyping and Testing

Building prototypes of the SPMs to validate their functionality, performance, and reliability. Testing involves simulating real-world operating conditions to identify any design flaws or optimization opportunities.

Optimization

Iteratively refining the design based on feedback from prototyping and testing to enhance the efficiency, accuracy, and robustness of the SPMs. This may involve modifying mechanical components, fine-tuning control algorithms, or improving ergonomics.

Training and Knowledge Transfer

Conducting training sessions for operators, maintenance personnel, and other stakeholders to familiarize them with the operation, maintenance, and troubleshooting of the SPMs. Knowledge transfer ensures efficient utilization and maximizes the return on investment.

Body in White (BiW) Fixtures and Components Design

Assembly Fixture Design

Designing fixtures and jigs for the accurate positioning and assembly of body panels, sub-assemblies, and other components in the automotive body structure. This includes considerations for dimensional accuracy, accessibility, and ease of assembly.

Welding Fixture Design

Designing fixtures to hold and secure components during welding operations, ensuring precise alignment and weld quality. Fixtures may incorporate clamping mechanisms, locating pins, and adjustable features to accommodate variations in component geometry.

Robotic Welding Cell Integration

Integrating robotic welding systems with BiW fixtures to automate welding processes and optimize cycle times. This involves programming robot trajectories, specifying welding parameters, and ensuring compatibility with fixture designs.

Quality Assurance

Implementing quality control measures to ensure that BiW fixtures and components meet the required quality standards and specifications. This may involve inspection protocols, non-destructive testing, and statistical process control.

Tolerance Management

Managing dimensional tolerances and variations to ensure proper fit and alignment of BiW components during assembly and welding. This may involve implementing compensation strategies, adaptive features, or tolerance stack-up analysis.

Ergonomics and Safety

Incorporating ergonomic considerations and safety features into fixture designs to optimize operator comfort and minimize the risk of injuries. This includes designing fixtures with ergonomic access points, ergonomic handles, and safety interlocks.

Datum and Reference Systems

Establishing datum systems and reference points for accurate measurement, alignment, and assembly of BiW components throughout the manufacturing process. Datum features are critical for maintaining dimensional consistency and quality control.

Process Optimization

Continuously evaluating and optimizing BiW assembly processes to improve efficiency, productivity, and quality. This may involve analysing cycle times, identifying bottlenecks, and implementing process improvements such as lean manufacturing principles.

In summary, designing SPMs and BiW fixtures and components encompasses a wide range of tasks spanning conceptualization, design, prototyping, testing, documentation, manufacturing support, and process optimization. Collaboration between design engineers, production engineers, technicians, and other stakeholders is essential to ensure that the designed solutions meet the specific requirements and objectives of the manufacturing processes.

We use the latest Catia/ Solid Edge/ Solid Work/ AutoCAD software and simulation tools to create detailed designs that optimize performance, efficiency, and ergonomics.

Whether you require simple jigs and fixtures or complex automated SPM systems across Pune, we have the expertise to design solutions that meet your exact specifications.

Frequently Asked Questions (FAQs)

1. Who is a reliable Special Purpose Machine manufacturer in Pune?

Shinerobo is a trusted Special Purpose Machine manufacturer in Pune, offering custom-designed SPM machines for automation, assembly, testing, and industrial manufacturing requirements.

2. What types of Special Purpose Machines does Shinerobo manufacture?

As an experienced Special Purpose Machine manufacturer, Shinerobo designs and manufactures customized SPM machines for automotive, engineering, electronics, packaging, and manufacturing industries.

3. Do you supply SPM machines in Pune?

Yes, Shinerobo is a leading SPM machine supplier in Pune, providing end-to-end solutions including machine design, manufacturing, installation, and commissioning.

4. What is an SPM machine, and where is it used?

An SPM (Special Purpose Machine) is a customized industrial machine designed to perform specific operations with high efficiency, accuracy, and productivity. These machines are widely used in manufacturing and automation processes.

5. Why choose Shinerobo as an SPM machine manufacturer in Pune?

Shinerobo stands out as an SPM machine manufacturer in Pune due to its customized solutions, advanced engineering capabilities, quality standards, timely delivery, and reliable after-sales support.

6. Do you provide customized Special Purpose Machines?

Yes, as a professional Special Purpose Machine manufacturer, Shinerobo specializes in fully customized SPM machines tailored to specific production needs and industrial applications.

7. Does Shinerobo offer installation and support services for SPM machines?

Yes, Shinerobo provides complete services, including SPM machine installation, testing, commissioning, and technical support across Pune and nearby industrial areas.